Extrusion Know How

Water, Oil, Air, or None?

There is no one 'best' barrel cooling medium, but there seems to be a shift in the industry toward air cooling.

Read MoreWell, It Worked on Brand X

You need to give your designer a lot more data than that to make sure you get a screw that's right for you.

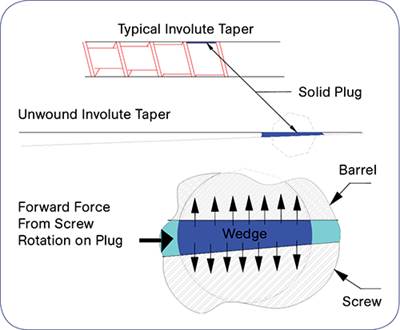

Read More‘Wedging’ Can Cause Severe Screw Wear

In a column I wrote for the July 2011 issue, I discussed the value of conducting “forensic” examination of worn screws when they are removed for clues to design flaws.

Read MoreHow Fillers Impact Extrusion Processing

Their addition can significantly change the processing properties of a polymer.

Read MoreBenchmark Your Extruders For Quicker Processing Fixes

Not recognizing output reductions and resolving them quickly can cost a lot of money. Benchmarking your machines will help.

Read MoreThe Truth About Barrel Heating

The main purposes of the heaters are to melt the polymer that remains in the barrel at cold startup, to assist in forming the initial melt, and to “trim” the barrel temperatures for specific purposes such as improving feed rate.

Read MoreWhere Does Shear Heating Occur? Here’s How to Find Out

One of the least understood yet most important concepts is viscous dissipation, which is the shearing or stretching of the polymer between the rotating screw and stationary barrel, causing heat to develop in the material.

Read MoreDead Screw Talking

There's a lot you can learn by conducting a post-mortum examination of your screw.

Read More